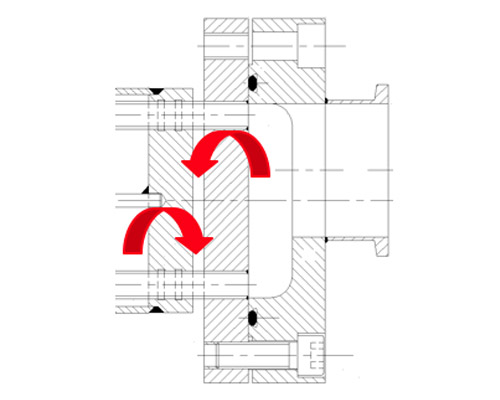

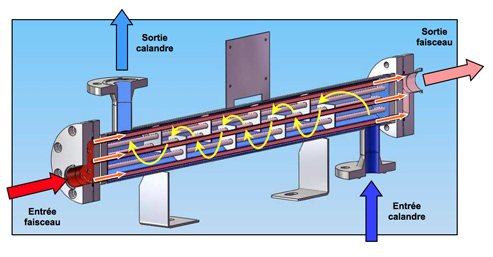

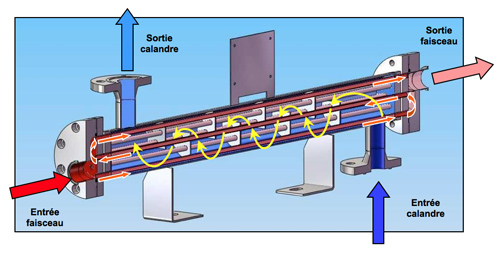

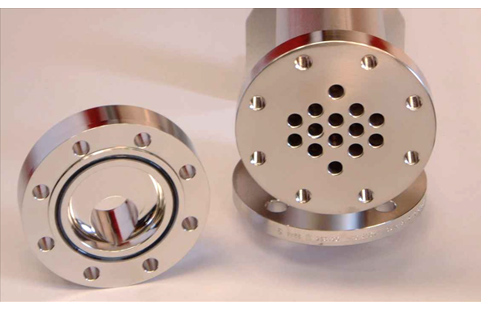

This range of heat exchangers comprises DTS (Double Tube Sheet) exchangers, as defined in the ASME BPE.

The specific design of the Pharm’ACM exchangers prevents contamination or the development of bacteria in process water production and distribution systems.

Pharm’ACM exchangers are individually designed by our thermal engineers for each application, to meet the thermal and hydraulic requirements of the pharmaceutical industry, Feel free to contact our engineers and benefit from their long experience of pharmaceutical system thermal design